The Construction of Space Shuttle Launch Complex 39-B

A very personal and technical written and photographic history, by James MacLaren.

Page 18: Column Line 7.

| Pad B Stories - Table of Contents |

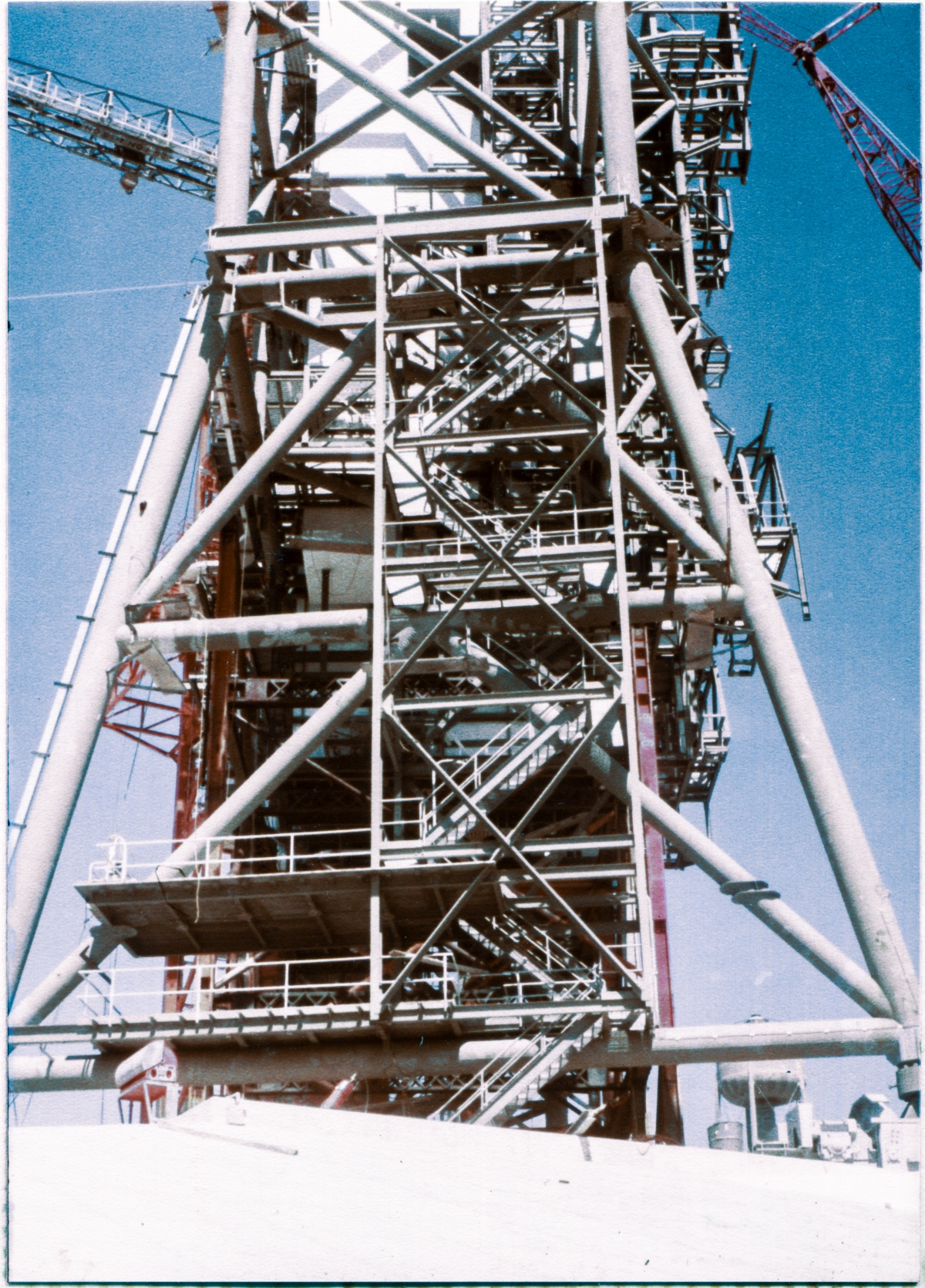

And when you walk out from underneath the falsework into the brilliant daylight, hoof it south southwest half-way down the west side of the Pad Slope over there, and then turn around, this is what you see looming into the sky above you.

Column Line 7.

A truly amazing thing, all by itself.

And you're staring right at it.

Aside from the Hinge Column, the two large slightly-slanted members going from the ground up near both edges of the frame are the heaviest iron in the whole tower, and weigh a very-respectable five-hundred fifty-seven pounds per running foot.

As with the Hinge Column, which is all the way across to the far side of the RSS, not visible from where you're looking at it now, and which we took a deep dive into back on Page 8, Column Line 7 carried half of the RSS's total four-million pound weight, so you're looking directly at iron that will be carrying a load of two million pounds after Wilhoit's Falsework has been removed.

This is a substantial weight, and, unlike the Hinge Column which stayed put and simply allowed the RSS to pivot around via the action of its bearings, Line 7 actually traveled while it bore its mind-boggling loads, and the business of starting, entering a state of motion, and then stopping, introduced dynamic effects, introduced dynamic loads, that the Hinge Column never experienced.

And so Column Line 7 was different.

It was stronger.

Down on it's lower end, it sat on top of the Truck Drives (we'll be getting into the Truck Drives down near the bottom of this page, ok?) which pulled and pushed the RSS along its curved set of rails, and it was supported at its bottom extremity with a pair of repurposed Spherical Bearing assemblies that were originally part of a set of MLP Mount Mechanisms (we'll be getting into the MLP Mount Mechanisms later on too) which were originally installed in the VAB.

Here's contract drawing 79K14110 M-8, telling us about the reactions that the bearings in Line 7 had to take into account.

Pretty substantial loads, both static and dynamic.

One day, maybe, I'll tell you a story, which was shared with me by one of the engineers who was directly responsible for this stuff, about the ultimate strength (which is the failure strength, the strength at which things actually come completely apart in catastrophic-failure mode, and break) of the wheels in these things (which were, out on the Pad, interchangeably called the Drive Trucks or the Truck Drives, depending on... I have no idea), and how you can, under very particular "just-so" circumstances, cheat the system and get away with something you have NO business getting away with, but not now, ok?

Heavy iron.

Heavy Bearings.

We're gonna dive in, like we did with the Hinge Column Bearings back on Page 8, and then dive in even further, down into the Truck Drives themselves, but allow me to digress for a bit, before we pick it up in earnest, farther down this page, ok?

Stair Tower 3 is shown well in this frame, too, and from this angle you can see how they built half of it outboard of the Primary Structure of the RSS, and had to hang a fair-sized wide-flange beam out there past Line 7 itself, between Lines A and B, to support that side of it.

Nobody ever used that stair tower for anything.

Except me, of course.

No end of spectacular wide-open views from that thing could be had off to the south and west from the top of it, and when you got down below the RSS Main Framing at 135'-7" the views broadened in scope to encompass vistas to the horizon at compass points with east and north in them, and then very much moreso once you were down below the sensible body of the RSS at elevation 112'-0", and I would come down off the tower going the long way around, on foot, using Stair Tower 3 instead of the FSS elevators, pretty much every chance I got when time permitted. Between the view, and the near-complete silence and isolation over there, it was one of my favorite places on the whole set of structures.

Going up from the left side of the top of the stair tower, you can see the white blandness of the insulated-metal paneling that enclosed the PCR Elevator, and the Elevator Lobby which had a peculiarly triangular floor plan, and if you look close, near the top of it in this image, you can see that the triangularity of the lobby layout becomes apparent along the big cutout near its top edge as well as where a shadow from one of the big Primary Framing pipes is cast upon it, just below that.

Partially obscuring, and immediately to the right of the PCR Elevator Lobby paneling, the riser-treads and x-bracing of Stair Tower 4 can be seen, extending upward, out of the frame.

To the right of that, past the vertical Primary Framing members of Line 7-B and also Line 5-C, the latticework of the RCS Room framing steel and associated SRB Access Catwalks and Platform framing continues to get added to by Wilhoit's crane, and from this angle you can get a bit of an idea as to how that steel cantilevered out over completely empty space with a free drop of over 150 feet beneath it, all the way down to the Pad Deck.

Below that, a bit of Vehicle Access Platforms, and farther down, PBK & Contingency Platform framing is visible

And then we get into those evanescent things that come and go in the blink of an eye.

Or maybe not.

Sometimes some of this stuff will stay right where it is, for literal months.

It all depends.

If you're going to be somewhere for a while, perhaps engaged in making a large full-penetration weld on some big pipes, you can just grab some 3x3x¼ angle-iron and weld it to the piece you're working on, and then lay metal pickboards or plain wooden planks across it, and you're good to go.

Union Ironworkers don't take "no" for an answer, and if the world fails to provide them with what they need to do their work, they'll just go right at it anyway, provide for themselves, and not even bat an eye at it.

I distinctly remember being more than a little bit surprised and frightened when I first saw one of these setups. They very much do not look substantial in any way. Those spindly-looking pieces of angle-iron just sort of stick out there, unsupported by anything, and they give a strong appearance of being... brittle, or weak, or something else equally-unpleasant and unsettling, and the thought of hanging your own personal self off of a thing like that can give you a case of the shivers if you don't know how stuff like this really works.

3x3x¼ angle-iron is amazingly-robust stuff at human-scale, and when you hit it with some fillet-weld to tie it to another sensible piece of structural steel, what you wind up with is ridiculously-strong at human-scale, and can be trusted with your life and everybody else's life too. And I would suppose that it's a little like packing parachutes. You pack your own parachute, and that way you know it's packed right, and if you weld your own angle-iron to the structure before you put a board or two on it to sit down on and go to work for a while, you're gonna know that's been done right too.

And so that's how they do it, and not only does nobody ever fall off the tower, they've also created for themselves one of the best possible working environments you could imagine. Eagles building nests on the sides of cliff faces in the mountains don't have it any better. Pull the welding hood down, strike an arc, and go at it. And when you've finished the rod, lift the hood, reach into your rod-can for another, and maybe stop for a few moments. To rest for a brief moment. To take in the view for a brief moment. To appreciate the unblocked sky above your head and a complete absence of walls, and desks, and cubicles, and cash-registers on countertops, and all the rest of what lesser mortals must deal with on a daily basis, all around them, hemming them in. To thank your lucky stars that you're presently in a place where NObody can get to you, and the mere fact of being there confers full qualifications of being a bad-ass, with all of the rights and privileges appertaining thereunto. And then you return to your task with an untroubled mind, thanking your lucky stars that you successfully overcame your initial gut-wrenching fear of heights when you first went up there, up on high steel, and were able to handle it well enough to gain full acceptance into a very small club, that no one else is given entry to.

This photograph was taken right around noon, and that can be determined by the direction of the shadows.

And there's nobody on any of these little work platforms that are sprinkled all over the tower.

Which means one of two things, or perhaps even a little bit of both at the same time.

Everybody was in the shade somewhere else, eating their lunch, taking a well-earned break.

Or this end of the overall work effort was done, and the platforms had been left in place until all of the welding inspection which follows this kind of work had been completed.

And of course if any of that welding inspection was radiographic, then that particular person or crew of specialty welding inspectors would never be seen during regular working hours, and instead were generally summoned for visits in the middle of the night when everybody else was gone and the pad was deserted, to minimize as much as possible, any chances for human exposure to any potential hazards associated with taking your little box of Cobalt 60 up on the tower to use as a "light" source for sending X-Rays through the weld in question and hitting a piece of photographic paper on the far side of the weld, to be developed and examined later on.

These welds were all that was keeping the whole damn thing up in the air, in one piece, and NASA and everybody else took this stuff seriously, and it had better be right, or it gets redone until it is right, but skilled welders know how to do it right, so it's all good.

Not all of the temporary work platforms are held up in the same manner, and ironworkers will do what's required, and work around and work with, whatever they've been given to deal with at any individual location.

Look close at the image, and you'll see that in several places, the supporting iron has no planking or pickboards on it.

Maybe the work's done and we've taken the boards down, but haven't had time to come by with a torch and finish things off all the way.

Maybe the work's done but we're leaving the angle iron in place so we can put the scaffoldboards (which we needed elsewhere for a little while) back in place once again when time comes for the welds to finally get inspected and bought-off.

Maybe something more important came up, and a good hand was needed elsewhere for a while.

There's just no way to know.

But what I do know, is that it's just about a sure thing that I missed some of this stuff somewhere, when I was going over this photograph with a fine-toothed comb, looking for it.

It's not easy.

It's pretty bewildering up there, and there's got to be a few places that I missed.

But that's ok. At least you get to see enough, right?

You get to see how they do it.

And way down in the lower-left end of things, just left of the apex of the pad-slope concrete, there's a little barbecue-grill-looking thing, but we're not gonna be having a barbecue out at the pad today, ok?

That thing is a camera mount, and I'm pretty sure it's this one, and it has a roll-down metal blast-cover to keep things from getting blown to hell when the Shuttle takes off.

So no barbecue today, ok?

Ok. Now that all that's out of the way, the time has come to bear down on it, and see how Column Line 7 works, down at its bottom end, down where 2 million pounds of weight passes through it, on its way to the ground, which, of course, is what ultimately holds everything up, except for maybe stuff that's flying, but nothing flies forever, so...

One of the things on Column Line 7 that doesn't show very well on our photograph is where Line 7 connects to the Truck Drives beneath it, but alas, I never took a proper close photograph of that area, and as a result do not have one, and I think I'm just going to go ahead and use what I have, here, as a launching-off point for this whole system.

There's some amazing stuff in there, and it's well worth our time to dig in to it.

We'll work from high to low, and the first thing we'll be encountering is the Spherical Bearings that tie the Heavy Iron of Line 7 to the body of the Truck Drive.

And to do that, we'll need to back up, all the way to the Apollo Program back in the 1960's, because our Line 7 Spherical Bearings on Pad B (and Pad A, too), were cannibalized from existing equipment, and that existing equipment was the Mount Pedestals for the original Apollo Mobile Launchers, the giant things that the Saturn V sat on top of, which you will hear me referring to as LUT's a lot of the time, because this is the language I learned out at the pad, back when the last one of those LUT's still existed, intact, and that's what everybody, with no exceptions, always called it.

"LUT" is also what the whole Mobile Launcher gets referred to, often-enough, on the original Apollo drawings, and just to liven it up some, you'll also occasionally see it as "L-UT", or sometimes even "L·UT", so... just another little linguistic discontinuity to stub your toe on, if you come upon it unawares, carrying preconceptions to the contrary as baggage. Yes, the Launch Umbilical Tower can, very strictly speaking, be defined as only the 400-foot-tall tower which sits on top of the Mobile Launcher box, and when enunciated as three words, it almost always means exactly that, but you also can, with equal (actually, greater) justification, refer to the whole thing, box, tower, and all, as a "LUT" and not be wrong about it that way, too. Just so you know, ok?

The available information at my disposal (for the time being, anyway) is pretty thin on the ground, but I've managed to track down material call-outs for the Spherical Bearings on Pad B, and they're quite different from the Spherical Bearings we've already been introduced to on Page 8, over at the Hinge Column. I have yet to cross paths with the material callouts for the Line 7 Spherical Bearings at Pad A, but for the time being, I'm going to go with the Pad B callouts. And those callouts tell us that our cannibalized Spherical Bearings had no bronze in them. It was steel-on-steel with these Bearings, unlike the bronze-on-steel we learned about back on Page 8, with the Hinge Column Spherical Bearings. So we haven't even gotten started with it, and it's already a mess. Sigh.

The Mobile Launcher Mount Mechanisms were originally designed for Project Apollo by Harry A. Balke Engineers, and even without containing a proper material callout, that .pdf file I just linked to is well worth reading, and it contains a lot by way of design execution, as well as the design principles which dictated the particulars of that execution, and subsequent fabrication and erection, too, back in the 1960's. My guess is that all of the Spherical Bearings in all of the Mount Mechanisms would share a lot of commonalities, and Bearing Materials would seem to fit well among the rest of it, but...

...I don't actually know for sure, and unless something comes along to give me solidly-documented proof, you need to be aware that although the Pad B Line 7 Bearing Materials are definitive, the Pad A Line 7 Bearing Materials are not. Be warned.

So maybe let's see if we can get a look at what got cannibalized. From what originally got furnished and installed, back in the early 1960's, which was then repurposed for what was getting furnished and installed in the early 1980's.

From what originally got furnished and installed per things like Apollo Program Drawing Package 75M05121.

Here's 75M05121 sheet 1, which is the cover sheet for the whole package, and this drawing package contains some breathtaking stuff, not all of it even properly "technical," and some of it holds the power to send a cold shiver down your spine, when you stop and...

...think about it.

75M05121 is the Mechanical and Electrical package for the Saturn V Mobile Launcher, and sheet 1 is showing us a thing that had not yet even been built, traveling across a flat landscape, with a few palm trees showing above the distant horizon, at a place called "Cape Canaveral Missile Test Annex, Florida," dated October 1, 1963, less than two full months before the fateful date of November 22, after which many things changed, including the placename given to us on this drawing.

And of course the ML's had to be supported on something during those times when they were not actively mobile (and also when they were originally getting built over at the Park Sites north of the VAB), and the things that did the supporting were the Mount Mechanisms, and they were all over the place, in sets of six, not all six members of any given set being exactly the same, and we're not going to be delving down into the particulars of that little item right now, but rest assured we'll be revisiting it, later on in this thing.

The Mount Mechanisms were up on the Pads, and they were inside the VAB (four separate sets of six, one set in each High Bay), and they were over at the Park Sites (three separate places, one for each Park Site), too.

So, following the demise of the Apollo Program, NASA found itself well-endowed with unused Mount Mechanisms (excepting of course the places where they were still being used, holding up a leftover LUT which would never again feel the flames of a Saturn), and when the Rotating Service Structures for Pad A and Pad B got to a point where the basic design was pretty much frozen in, that basic design included the use of Spherical Bearings over on the bottom of Column Line 7, and those Spherical Bearings were cannibalized for reuse, taken from that which already had been furnished and installed for the Apollo Program, but of course it can't be simple, and instead it turns into quite the convoluted tale, and things were done differently, one way at Pad A, and a different way at Pad B. Stay with me here, we'll get it all sorted out in the end, I promise.

For now, it's enough to know that some of the Mount Mechanisms had "outriggers." Struts, to be precise. And some of the Struts had large Spherical Bearings down on their bottom ends, like the Strut you see labeled here on Original Apollo Drawing Package 75M05120, sheet 71 in a general arrangement elevation view of one of the Type II Mount Mechanisms, and it was those Spherical Bearings which were deemed the best match with the requirements for the Spherical Bearings which the RSS was going to need over on Line 7 at Pad A, so it was those Mount Mechanisms, the Type II ones, the ones with the large Spherical Bearings at the bottoms of their Struts (not all of the Struts had large Spherical Bearings down on their bottom ends, and some of 'em had small ones, and... it gets complicated, and you'll see just how complicated it gets in a minute here) that wound up getting grabbed.

And the ones they grabbed, were grabbed oddly, from differing locations.

For Pad A, 79K04400 sheet M-128 tells us to grab them... one from the Pad Deck (seems eminently reasonable, it's right there after all, nice and easy to get to), shown here on 79K04400 sheet M-125 (poorly, but it's there, and you as a contractor had best be able to deal with this kind of "poorly" or else you might find yourself in bankruptcy court), and a further complication, a further bit of interestingness, consists in the fact that this Mount Mechanism gets kept on the Pad, and will be used to hold up the Space Shuttle's MLP when it's rolled out to the Pad, but for whatever reasons, they're cutting the Strut off of the side of it and cannibalizing the Spherical Bearing from the bottom end of the Strut, and then throwing the rest of the fatally-wounded Strut away. No, I do not know the engineering rationale behind this one. I do not know why they decided that a Mount Mechanism Strut which was necessary for Apollo became unnecessary for Shuttle, but... that's what they did. They kept the Mount Mechanism, but tossed the Strut after grabbing the Bearing. Weird.

...and the other one was grabbed from MLP Park Site 1, and we get told to look at 79K04400 sheet V-7 for the location of Park Site 1, but otherwise, V-7 is of no use at all, and I have no idea which Mount Mechanism got hatcheted to render up the Spherical Bearing, it having happened long before I ever showed up, and I'm guessing that this was one of those deals where Cecil Wilhoit sauntered over to the NASA trailer and simply asked them, and without further ado sent crew and equipment over there to go at it, and yes, without any question, there was paper, somewhere, with specific instruction on this one, but back in those days, the level of trust and the level of integrity between parties was such that a lot of time-consuming bullshit and ridiculously-unnecessary expense was just skipped over as Cecil Wilhoit and NASA... went at it. And it got done right, and everybody benefited, and the Foul Odor of Lawyers never entered anyone's nostrils at any point along the way.

For Pad B, it was different. And it wasn't just a little different. It was completely different.

79K14110 sheet M-13 tells the tale.

And the first thing M-13 tells us, is that we're NOT using bearings from one of the Mount Mechanism Side Struts, but instead, we're using bearings from the main vertical COLUMN of the Mount Mechanism itself. Whole different thing. Whole completely different thing.

And after we've taken the hatchet to our designated sacrificial lambs, M-13 tells us to head on over to 79K14110 sheet M-65, and do some significant rework to our cannibalized parts, to make 'em work like they need to, down at the bottom of Column Line 7, bolted to the top of our Drive Trucks.

Just going by my own less-than-fully-qualified gut feeling about the differences, the main thing seems to be that the Spherical Bearings for Pad A had a steel Collar, or Retainer Ring, which would keep things together if the system was to ever, somehow, see any tension, while the Spherical Bearings for Pad B had no such component, and were strictly for compressive and rotational forces, only.

79K04400 sheet M-128 shows us our Spherical Bearing for Pad A, before it's been taken off the Strut, complete with a Collar, or Retainer Ring. And again, if the Spherical Bearing were to ever endure forces applied in tension, the Collar will hold it together, and it would happily remain in one piece, and not get pulled apart.

79K14110 sheet M-65 shows us our reworked Spherical Bearing for Pad B, now located on Column Line 7, and it does not have, nor did it ever have, any kind of Collar or Retainer Ring. Whole different item.

And I'm guessing that somewhere along the line, somebody looked at what they spec'd out for Pad A which was grabbed off of the Mount Mechanism Strut, complete with the accommodation for potential forces which might put the Bearing in tension, and then they looked over at the 4-million pound RSS, and then they thought about that for a few moments, and then they decided, "If we're worried about these Spherical Bearings over here on Line 7 ever seeing any kind of tension, in any form or manifestation, then my guess is that having the Bearing come apart is going to be the LEAST of our worries, and if whatever god-awful kind of thing, that might cause some tension in the Bearing, ever pays us a visit... the whole fucking RSS is going to be in the process of vigorously jumping up and down, or tipping over, or flying away, or... and ya'know guys, how 'bout we just kind of skip all that tension rigamarole, and just go with a purely compressive bearing grabbed from the Mount Mechanism Column, and let that be good enough, ok?" That said, there was that great big "Retainer Bolt" in there (here it is on one of the original Apollo Drawings, 75M05121 sheet 92, complete with Harry Balke Engineers in the title block), so I guess if the RSS did fly away, it would be able to pick up the Truck Drives right along with everything else, and take them too. I guess.

But of course I could be wrong, right? I mean, after all, who the fuck am I to question or second-guess the motivations of the Engineers who cooked this shit up, right?

So ok.

Whatever you want, Engineer Guys. We're just a lowly contractor and we'll do whatever you tell us to do. We're good with it, however you might want it.

Also, M-65 is where we get our specific material callouts for all of the Spherical Bearing components, and all of the callouts are done via ASTM Specifications, and all of them are steel. So that settles that, for once and for all. No bronze in this thing, ok?

M-65 is also one of the places where we get to see that great goddamned big Retainer Bolt that runs right through the center of the Bearing Hemisphere, and also runs right through the center of the Bearing Yoke without touching it!, and no, I have yet to definitively find out what's behind that little item.

The Retainer Bolt holds the Bearing Hemisphere firmly against the heavy steel plate at the very bottom of the Column Line 7 Primary Framing Steel Pipes, and it does that via the slight "shoulder" on it (which we just saw on 75M05121 sheet 92) where its 3 3/4" shoulder diameter hits and hard-interferes with the 3 9/16" hole in the domed surface of the Bearing Hemisphere, allowing us to crank down on that Bolt by turning it, and that Hemisphere ain't going nowhere after a thing like that's been done (but we're in a strictly compressive or rotational regime with these things, and I still can't figure out why they wanted to pin that Bearing Hemisphere up against the heavy steel it was sitting under as strongly as they wanted to, but forget that), what the hell's going on with drilling a hole through the Bearing Yoke, and having the head of that Retainer Bolt stick out through the hole, on the other side, but... no, you may NOT touch the Yoke with the Bolt.

Maybe one day I'll find out. Maybe one day I'll get to tell you all about it.

But not today, alas.

But I can keep guessing at it, 'cause it's fun, so that's what I'm gonna do, just for shits and giggles.

The VAB Mount Mechanisms were designed and constructed for "indoor use" and would never be seeing "outdoor" loads, and for that reason were built just a trifle "lighter," and down at the bottoms of their Columns and Struts, their Spherical Bearings were not expected to see any kind of sensible tension loading, and therefore did not have the Bearing Collar which the Spherical Bearings elsewhere (including what got cannibalized for Pad A) had.

But goddamnit, they wanted that Bearing Hemisphere pinned, and the fucking Retainer Bolt has a three and a half inch diameter ASTM A354 Grade BC shank on it, and that shank has a yield strength (not, ultimate, not breaking, but instead simply the maximum allowable... of over 950 ksi. Over 950 thousand pounds! And why the hell they wanted that kind of force (yes, I know, the actual applied tension on the bolt shank is going to be significantly reduced via the safety factors they used, but even then, it's still a lot of force) to be appliable through that Retainer Bolt, I'm sure I shall never know.

But somebody, somewhere, deemed it necessary, and designed accordingly, and I suppose maybe that's why the fucking Retainer Bolt goes through a hole in the Yoke, without being allowed to touch the Yoke, 'cause there was no other way to get that kind of force on that Bearing Hemisphere using something set down in some kind of a countersunk depression in the Hemisphere, without the concomitant need to extend it out and through the Yoke, and doing it that way.

But who the fuck really knows?

Not me, that's for sure, but there it is, anyway, and maybe you go figure it out, hmmm?

And just for comparison, here's 75M05120 sheet 73 (unfortunately-poor drawing quality, but it's good enough, nonetheless) showing you the Lower Spherical Bearing on the outdoor use Mount Mechanism Column, and that Bearing Collar is loud and clear, ready to rumble, ready to deal with some serious tension, should something come along and maybe try to tip things over, or bounce them up and down... like maybe a hurricane, or maybe a Saturn V cutting loose and suddenly heading for the sky.

And if you're sitting there thinking to yourself, "Yes, that's all very nice. It's wonderful in fact. But why the fuck did they even put this whole ridiculously-contrapted Spherical Bearing shit down there underneath the Primary Framing of Column Line 7 in the first place?

The goddamned RSS isn't going anywhere, right? Or wherever it goes, Column Line 7 and the Truck Drives directly underneath it are both going to the same place right along with it, right? It's not like some of it's gonna go here, while the rest of it's gonna go there, right?

So whuffo?

And right back we go to John M. Crump's motherlode, Mechanical Features of the Shuttle Rotating Service Structure, which we first crossed paths with all the way back on Page 1 of this thing. There was no way any of you could have grokked the full implications of that whole document at the time, though, so I'm taking us back there once again right now, to Page 3, where John explains the need for our ridiculously-contrapted Spherical Bearing System, out there on Line 7, down at the bottom, where it sits on top of the Truck Drives.

Running the numbers for the coefficient of expansion of structural steel for our 160-foot wide RSS, over the cold-winter to hot-summer temperature range you get in East Central Florida, spits out just under a half inch variation in the 160 foot width of the Rotating Service Structure. And this might not seem like much, but down on the ground, where the steel wheels of the Truck Drives are resting on top of the curved rails they travel across, that half inch translates into some significant sidewise forces, which have the power to cause us real trouble, in obvious ways, and in a few very unobvious ways (you figure it out, I'm not gonna tell you), and so perforce, we must accommodate for it, and so we do, and so we put Spherical Bearings down there on top of the Truck Drives, to accommodate for thermal expansion and contraction, keeping everything exactly where it belongs, feeling only those forces we want it to, as it does so.

Those Spherical Bearings aren't going to be moving much. Hardly at all, in fact. Looking directly at it, you wouldn't even see it. It would make the moving hour-hand on a clock look like an arrow flying through the air by comparison.

But...

They are moving...

And in so doing, they're keeping everything else right where it belongs, and for that reason we need them, and so we have them.

Which brings us at long last to the Truck Drives, sitting directly beneath our Spherical Bearings out there on the bottom of Column Line 7.

The things which drive our RSS along its set of curved rails, from its "de-mate" position sitting back out of the way, south and a little west of the FSS, to its "mate" position, where it interfaces with and services the Space Shuttle sitting on its Mobile Launch Platform, straddling the great gash of the Flame Trench, east of the FSS.

These things, which you can see an example of in a nice multi-view orthographic projection, on Pad A drawing 79K04400, sheet M-126, and note the distinctive Pad A Spherical Bearing with the Collar, which the Pad B Spherical Bearing lacks.

Here's the Truck Drive on an unmarked Pad B drawing, 79K14110 sheet M-11, and you can see that it's different, and the drawing itself is looking at it differently too, with different section cuts, and these things were complicated, and one of the reasons they were complicated, was because they were not simply wheeled-carriages with Column Line 7 bolted down on top of them, but instead, they were very-carefully-designed to prevent that 2-million pound dead load (and all the happy little live loads associated with having and moving that great goddamned big Rotating Service Structure which was sitting up there), coming down through Column Line 7, and becoming unequally distributed among the 8 wheels on each truck drive, in a way that might cause trouble.

Not enough evenly-distributed load here translates directly into having too much unevenly-distributed load there, and when you're dealing with forces like these, too much can be... not good. Not good at all.

And so, in addition to everything else the Truck Drive needed to be able to do (and there was plenty, whether it looks that way to your eye or not), it needed to be able to ensure that the load was coming down evenly on all eight of its wheels, and that was accomplished through a clever system of Load Equalization Pins, and it's that Load Equalization Pin System that makes these things look (and they are, too) as devilishly-complicated as they look.

And rather than have me go on and on and ON about it, we shall, yet again, pay John M. Crump's outstanding document telling us all about the Mechanical Features of the Rotating Service Structure, on Page 3, where I've highlighted the relevant paragraphs that John uses to tell us why the damn Drive Trucks had to be built the way they got built.

Further into the Truck Drives than this, I shall not go, and I shall not go there for two reasons. Reason Number One is that I'm not qualified, to do so. The Truck Drives were ferocious things, and the engineering that went into them was equally ferocious, and that brings us to Reason Number Two, which is that we could write a whole goddamned book about what goes on with the Truck Drives, and isn't this thing long enough already?

So ok. Enough already.

We've about beat Column Line 7 to death, as it is, and whatta ya say we award ourselves a little time off for good behavior?

I've got a few more tidbits about the Truck Drives that I'll share with you on the next page, but none of it is Heavy Reading, ok?

I promise.

Return to 16streets.comACRONYMS LOOK-UP PAGEContact Email Link |